A gear manufacturer has issued a safety alert after an accident on a French via ferrata following the suspected failure of one of its specialised lanyards.

Petzl said some of the lanyards – a special y-shaped sling for use on via ferrata routes – may be missing a bar tack which is an essential part of the energy absorbing system which protects climbers in a fall.

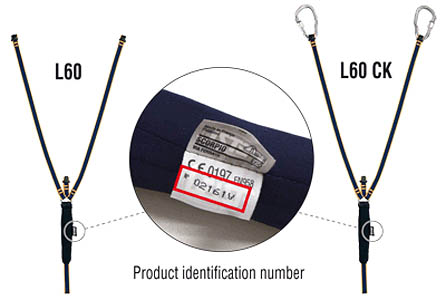

The alert affects only Scorpio L60 and Scorpio L60CK lanyards made before 4 March 2005.

The company, based in Crolles, north of Grenoble, said a man suffered a groundfall while climbing the Bastille via ferrata near Grenoble on 5 May. In a statement, the company president Paul Petzl said: “According to the latest information we have, the accident appears to have been the result of a manufacturing defect of the Petzl Scorpio lanyard – a version that stopped being produced in March 2005.

“The defect consisted of a missing safety stitch – or bar tack – on the attachment loop. Our first thoughts are with the young man and his family, to whom we express our deepest sympathies. They can be assured that Petzl will assume its responsibilities regarding this event.”

The company is asking anyone with such a lanyard, with serial numbers between 02150 and 05062 to return them to their local distributor which, in Britain, is Dent-based Lyon Equipment. Alternatively, anyone with concerns can ring Petzl on + 33 (0)4 56 58 22 60 or email them.

Petzl said the potential defect can only be seen if the energy absorber is removed from its protective pouch. Lanyards that pass the inspection will be returned to owners as quickly as possible, M Petzl said.

He continued: “Over the past 40 years, Petzl has manufactured several million pieces of safety equipment. This is the first known incident in the history of Petzl where an accident may have been the result of a manufacturing defect of a commercialized Petzl product. Safety is and has always been our first and foremost concern.

“We are constantly improving our manufacturing and inspection processes in order to reduce the risk of failure, most notably those linked to potential human error. The Scorpio lanyard has benefited from these perpetual quality improvements since the beginning of its production. All our safety products undergo a minimum of two quality control inspection phases: one during the manufacturing itself and then another independent final inspection.

“You can be confident in the commitment of every Petzl employee, each of whom is truly affected by this accident, that we will redouble our efforts to continually improve the quality of our products.

“Nobody can completely eliminate all risks, yet Petzl has always strived to do exactly that with regards to its products. Once again, we are going to carefully review our quality control procedures concerning production and safety stitching (bar tacks).

“I personally promise that we will take all necessary actions to immediately ensure this type of accident does not happen again.

“We ask you to accept our sincerest apologies.”

Via ferrata routes, using fixed cables, ladders, bridges and stemples, require special protection equipment. Standard slings are not suitable on the routes, which are found on various ranges in Europe.

Laurent de la Fouchardiere

20 May 2011Hello,

First of all i wish to thank you for actively forwarding to your audience the initial information on the Scorpio recall for inspection.

We have now updated our informations: Scorpio recall for inspection extended to all Scorpio via ferrata lanyards produced.

http://www.petzl.com/en/outdoor/news/products-news-0/2011/05/13/product-safety-alert-request-inspection-scorpio-via-ferrata

If possible please update the information on your website.

We are clearly aware of the problems caused by these actions and we ask you to accept our apologies for this inconvenience. Security is our greatest priority. The entire PETZL company is focused on resolving this issue as quickly and efficiently possible.

We greatly appreciate your help to inform all users.

Sincerely

Laurent de la Fouchardière

web community manager

SAS PETZL DISTRIBUTION

F38920 CROLLES